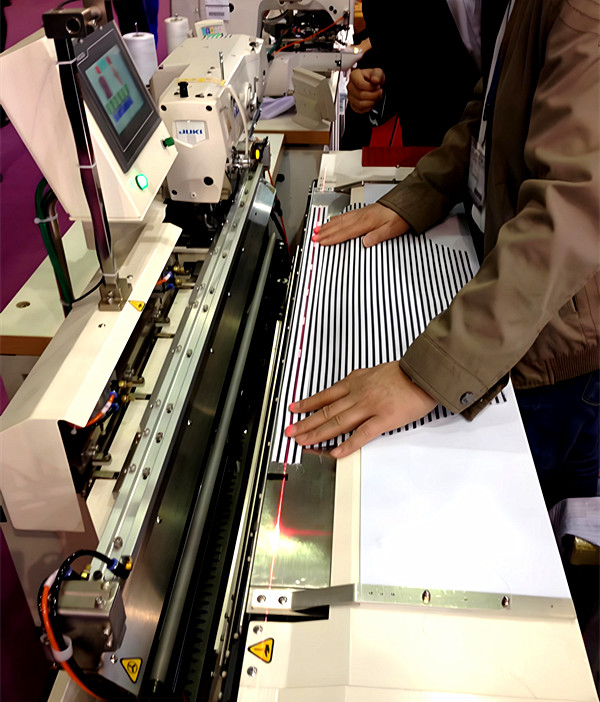

Red Line Laser Alignment Applied For Textile Processing

Are are getting serious need of ultra fine and straight line indication for a lot of garment processing and garment making works? If yes, on consideration of high accuracy and high efficiency guideline indication, economy red line laser alignment is widely used for modern time textile garment processing, design and manufacturing work fields.

Garment cutting

Accurate line positioning.

Red line laser alignment projects a highly straight red line via beam aperture, which is making good guideline indication for cutting job on garment cloths. It provides an accurate cutting red reference line for cutting equipment or workers, ensuring the straightness and accuracy of garment cutting, reducing errors caused by manual operation, and especially applicable for large scale cutting out garment with the same style.

Garment image position marking.

Garment pattern splicing.

For garments with spliced patterns, multiple sets of red line laser alignments can be used to project highly straight red reference lines at different positions. It is making accurate location of splicing points of the patterns, ensuring the accuracy and continuity of the pattern splicing, and making the overall effect of the garment more beautiful.

Garment sewing

Sewing guidance: A straight line projecting red laser alignment is installed on the sewing machine workbench. The projected red laser line can guide workers to accurately perform the sewing operation, making the seams straighter and more even. It makes good job for improving the sewing quality and efficiency, especially in sewing work of making straight seams, darts, etc.

Alignment point marking: There are always some parts on clothing that need precise line alignment, such as pockets, cuffs, collars, etc. The straight red reference line projected by 650nm red laser module can be used as a mark of the alignment point to help workers align the various parts to ensure the accuracy of sewing immediately and accurately.

Clothing ironing

Folding positioning: During the clothing ironing process, the red line projecting red laser alignment can project the folding line to guide the workers to fold the clothing in the correct position, ensure the neatness and consistency of the folding, and make the appearance of the ironed clothing more regular.

Ironing area indication: For some parts with specific ironing requirements, such as collars and trouser seams, the straight red reference line projected by the 650nm red laser module can clearly indicate the range and position of ironing, avoid excessive or inadequate ironing, and improve the ironing effect.

Clothing quality inspection

Flatness inspection: Install the economy red line laser alignment on the inspection equipment and project a straight line on the surface of the clothing. If there are wrinkles, unevenness, and unevenness on the surface of the clothing, the red laser line will be deformed, and the inspectors can quickly find the problem area based on this, improving the inspection efficiency and accuracy.

Size measurement: Using the angle and distance relationship formed by the straight red reference line projected by the 650nm red laser module and the edge or specific part of the clothing, combined with the measuring instrument, the size of the clothing can be quickly and accurately measured to determine whether it meets the specification requirements.

According to the requirement of line alignment and measurement accuracy and brightness, this Economy red line laser alignment enables freely selected output power and optic lens fan angle. It makes ultra precise and straight red reference line, thus provides garment processing workers ideal line alignment source for all work fields effectively.

Post Comments

You must be logged in to post a comment.

Click here to log in