Laser Alignment Working Principe and Usages

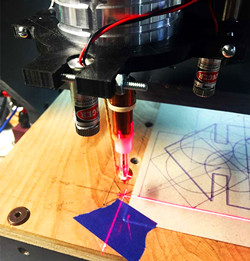

The adoption of laser light forming laser dot, laser line or cross line, laser alignment brings great convenience. It reduces the cumbersome process of manual line painting and line drawing, improves working efficiency, and avoids scene brought by artificial scribe.

Laser alignment users high performance laser tube, combined with high precision glass cylindrical lens, forming the most precise and accurate laser dot, laser line and cross hair. Laser light is always very bright, clear, uniform and high straight and collimate. In many special conditions, laser alignment tool can achieve the desired effect. Built in cooling system of metal heat sink is particularly suitable for harsh environments.

Laser alignment equipped with dedicated DC input power supply gets superior advantages of strong anti-interference, high stability, soft start and limit inrush current etc. It can effectively ensure product stability and long serving lifetime. The adoption of laser alignment system provides effective solution of extreme work intensity on artificial alignment.

Usages of laser alignments:

Special laser beam emitting principle and laser producing determine the special features of laser light. Laser gets the most featured characteristics of good monocles, good coherence, good direction and high brightness. The utilization of laser good direction and high brightness has made laser alignment widely used in medical treatment, military targeting, security, cast line instrument.

This advanced laser alignment system also gets wide application in precise machinery processing, including stone machinery, woodworking machinery, metal sawing machine, packaging molding machine, textile processing etc.

Whenever users are choosing laser alignment tool to make laser dot, laser line and cross line alignment, it is always providing direct, intuitive and practical alignment and collimation result. It is very easy and convenient to install, stable and reliable, can greatly improve efficiency of various processing tools.

Advantages of laser alignments:

● Laser alignment can completely replace the artificial line on cutting material, avoid not straight and not clearly manual line drawing and painting.

● The application of industrial alignment laser can truly realize online and real time laser line targeting, improve working efficiency greatly.

● Laser alignment tool supports 24 hours continuous work online, fully sealed design industrialization.

● Professional optical system designed laser alignment to ensure super laser line, laser dot and cross hair laser results.

● Laser alignment gets strong anti shaking ability, self-protection functions.

Laser alignment adopts excellent quality laser diode as core component, applying the latest communication technology and industrial alignment laser manufacturing technology, making it workable in various industrial product working fields. It gets high performance and incomparable advantages than other equivalent products.

Post Comments

You must be logged in to post a comment.

Click here to log in