How is a laser line generated?

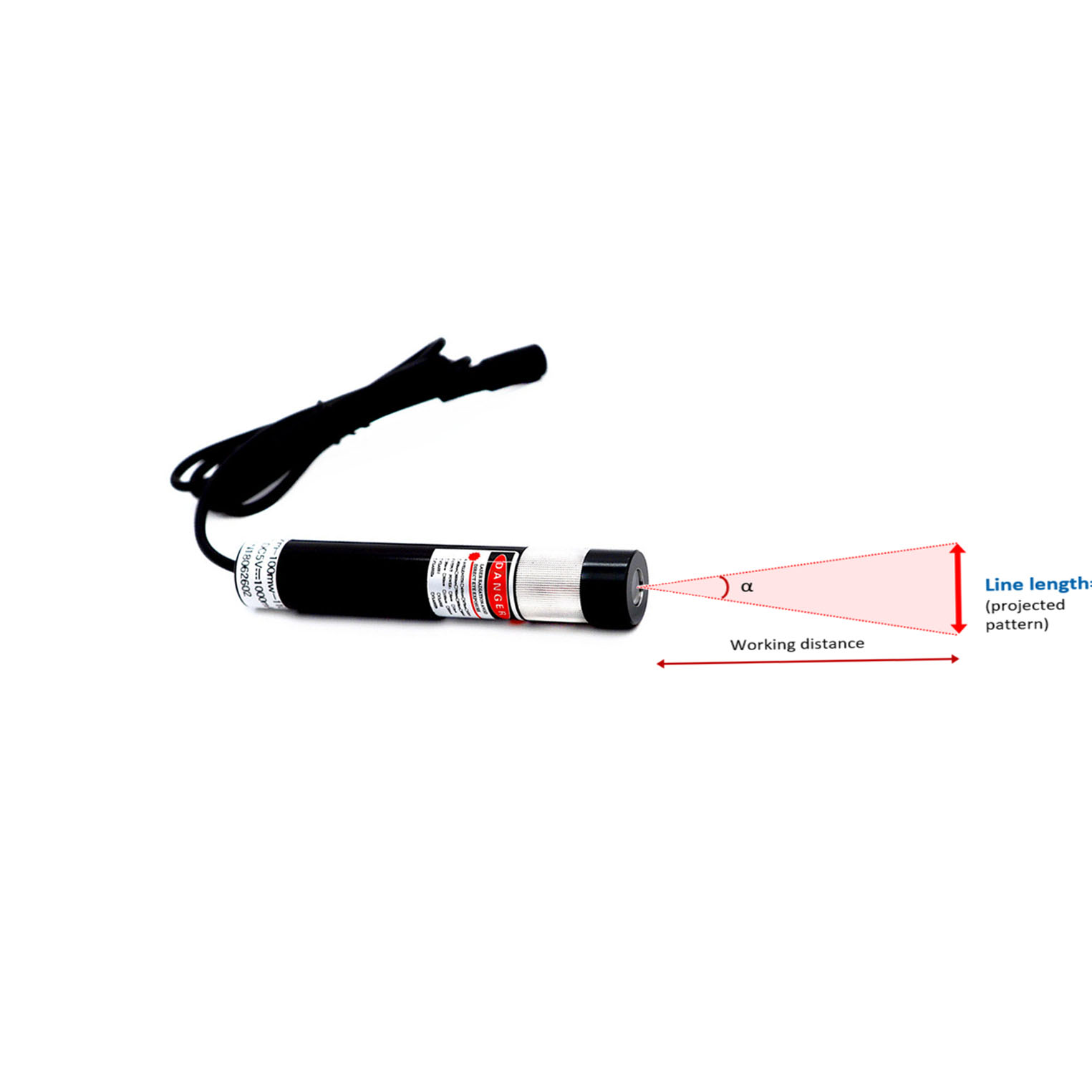

A typical laser device is projecting simple laser dot of laser beam aperture. A laser line is a different device that employs qualified glass coated lens or separate crystal lens(Powell Lens) with different fan angles. It is projecting special laser beam in type of a highly straight laser line, rather than a laser dot or point. Intense laser beam passing through a certain fan angle optic lens achieves a high linear quality and high fineness line in use.

Laser line is available with different line lengths, line finenesses. Either projecting laser light source via laser diode or DPSS laser system, but due to additional optical lenses, it produce narrowband coherent light. Available with wide fan angles of 10 degree to 110 degree, it projects various line lengths of 0.5 meter to 6 meters on basis of real work distance. For closer distance line measurement, it gets even finger and shorter line source on basis of the need, and allows the users to establish a horizontal or vertical line onto any raw material processing surfaces.

Laser light beam is created by formally used laser diode, which is a simple semiconductor which projects the laser light. When it is passing through a optic lens with different fan angles, it is not any longer projecting a simple laser dot, but produced into a special type of laser line. It is applicable for showing clear and fine lines for alignment and positioning. They can also be used to display lines for a lot of raw material processing works, including laser cutting machine, folding machine, glued machine, welding machine, milling system, and others etc.

Color - laser line wavelength

Within visible optical spectrums of 380nm violet laser to 780nm red laser, and invisible infrared laser line range of 780nm to 1470nm, which are able to project different color laser light and reference line in real use. There are a lot of typical used laser devices, covering 405nm violet, 445nm, 450nm, 460nm blue, 515nm, 520nm, 532nm green, 635nm, 638nm, 650nmm, 655nm, 670nm red laser, and 780nm, 795nm, 808nm, 820nm, 830nm, 850nm, 905nm, 930nm, 940nm, 980nm, 1064nm, 1310nm, 1470nm infrared laser lines. Berlinlasers is always providing users a reasonable price and quality reliable line aligning tool on basis of your need.

Laser beam intensity

Laser line beam intensity is decided by its output power measured in milliwatt (mW), which can be divided into different laser safety classes, Class I and II within 1mW, Class IIIa between 1mW to 5mW, Class IIIB lasers covering output power of up to 5mW to 500mW. Class IV laser covers even higher output power above 500mW.

Caution with laser lines with different output power

Laser users cannot stare at any output power made laser line. Although laser users cannot stare at any laser light, low power laser within 1mW to 5mW cannot hurt human eyes. The genuine use of laser line with higher power up to 50mW, it projects seriously powerful laser radiation and reflection, and thermal energy, which can cause serious hurt to retina or skins. Do be careful with any output power laser device, and remember to choose proper wavelength preventing laser safety goggles and glasses.

Post Comments

You must be logged in to post a comment.

Click here to log in